Design

Indepak has worked closely with our customers to design thousands of innovative packages and products over the years. We pay attention to space, weight, strength, presentation, cost containment, etc. so that you end up with the best solution for each application. The precision of our custom thermoforming team and the end products produced are of the highest level of quality.

To support your application with excellence, Indepak’s custom thermoforming design team collaborates with you from concept, through prototypes to ultimately provide production parts that meet your requirements.

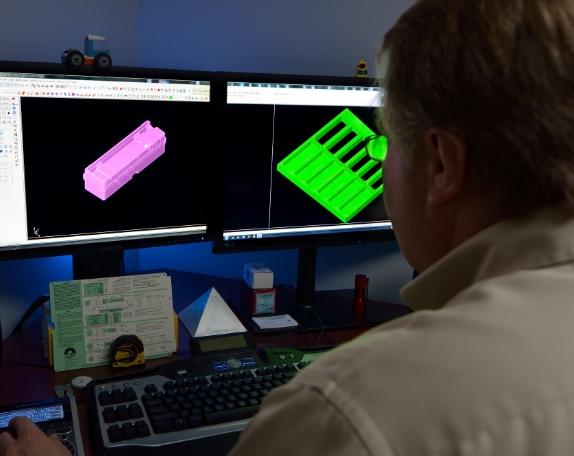

We utilize the latest technology to develop your part design, often starting with CAD files of your product. We will provide easy to understand solid model designs for review. Once the design is approved, we can quickly produce prototype parts for you to evaluate.

We work to fully understand your manufacturing process, marketing needs, merchandising and consumer needs, all to arrive at the optimal design. Our Engineering team has many years of experience in diverse applications. You will benefit from the knowledge that we have gained in working on a range of products and designs. We take the extra step of working with you on aspects such as retailer packaging requirements, aesthetic design, package assembly, efficient part nesting and de-nesting and material selection all while meeting your specific needs. Contact us to explore design possibilities for your application. We will be glad to discuss it with you.

Better Design Yields Better Product Quality

Delivering functional, effective, cost-engineered parts is a hallmark of Indepak value. We provide quality parts by designing and engineering well, up-front, both to fit requirements and to be producible efficiently and with quality, which speeds production and minimizes scrap. This is also the phase where we decide which process and equipment to use for production that will ensure lowest cost and best fit for the application.

Ready to Get Started?

Request Quote

and/or Samples

Contact sales for volume pricing and

access to free samples for testing and

prototyping.

Contact a

Packaging Specialist

For help finding the best package for

your application or creating one that

is customized to your specific needs.

Shop Our

Online Store

For immediate access to our stock

packaging tubes, clamshells,

containers, caps and more.