Thermoformed Trays

As one of the leading manufacturers of thermoformed trays with a specialty in precision thermoforming, our team is often tapped to develop and manufacture trays that other thermoformers struggle to produce. We combine a can-do attitude with sophisticated equipment and extensive experience in material selection, tooling design and processing to develop these solutions.

Food

From basic candy trays to precision-molded containers used in highly automated filling and packaging lines, we are FSC 22000 certified and experts in designing and manufacturing custom thermoformed trays for food packaging.

Medical/Pharmaceutical

Our success in this market can be attributed to our ability to manufacture low-particulate packaging for non-sterile or downstream sterilization applications along with detailed record keeping that ensures traceability down to the box level.

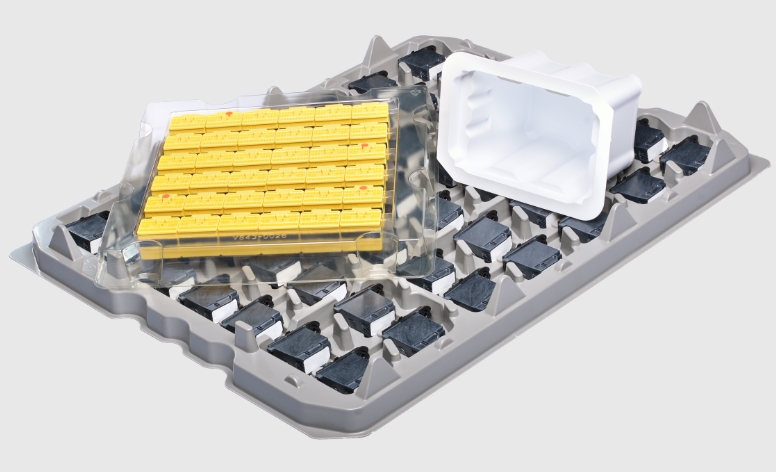

Electronics

We specialize in designing and manufacturing precision packaging and material handling trays featuring tight-tolerance cavities needed for pick-and-place automation in anti-static, dissipative and conductive materials.

Retail

Our experience in designing packaging trays and thermoformed plastic inserts goes beyond the typical supplier. We excel at collaborating with other packaging media suppliers especially when very precise or deep-drawn trays are required.

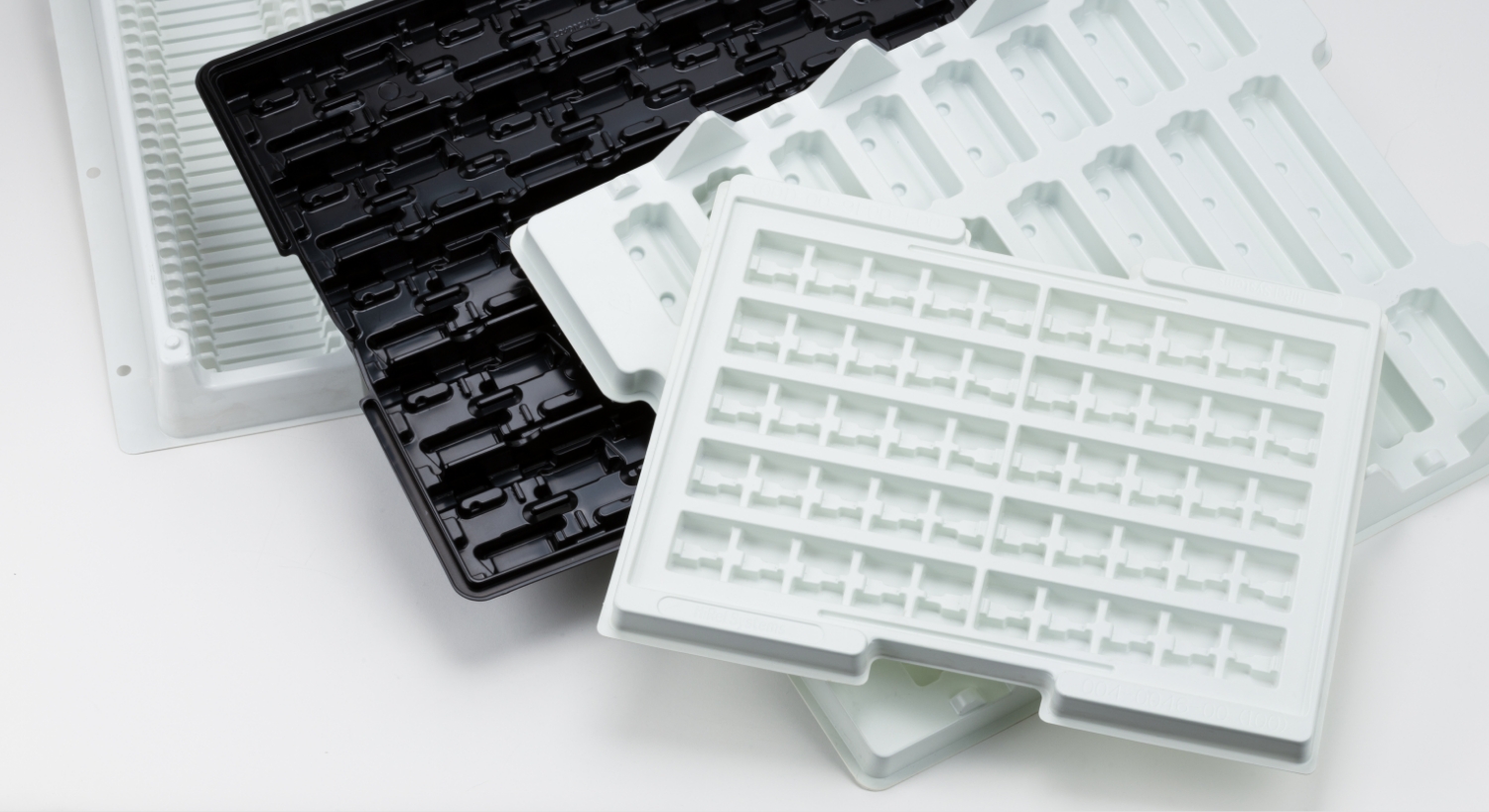

Industrial

We have extensive experience manufacturing precision trays and totes for storing, shipping and parts-handling applications used in automated operations. We work with many different plastics and can produce custom thermoformed trays in a variety of thicknesses with very tight tolerances.

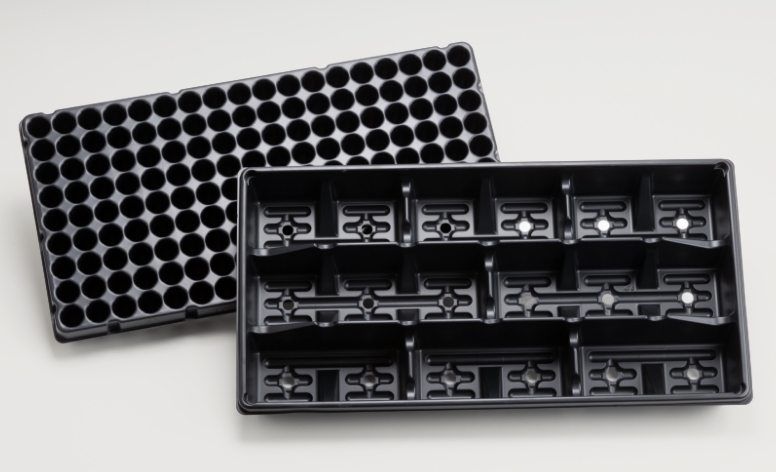

Agriculture

As a company focused on sustainability, we are proud to manufacture a number of trays that help optimize the planting of new trees and other plants. Our experience in manufacturing precision trays for high-volume applications has set us apart from others in the industry.

Lidded Packaging Trays

One of our specialties at Indepak lies in developing and manufacturing lidded trays for use in many medical, food and modified atmosphere packaging applications. We understand the importance for producing flat flanges for sealing lidding film to trays and often collaborate with our customer’s equipment and film suppliers to specify the proper barrier films, amount of silicone and other factors to achieve shelf-life requirements.

Innovative Designs

Whether you need us to integrate a “Rotate-to-Stack” design that reduces shipping and storage costs or something more complex, we are up to the challenge. Our custom thermoforming design team excels at developing custom molds, processes and even equipment to meet the needs of our clients.

Trays Used in Automation

We know that flourishing in today’s competitive marketplace typically requires a fair amount of automation. The Indepak custom thermoforming team has been at the forefront of developing trays that work in automated environments.

- We understand the requirements of parts feeding in automation, denesting, and close tolerance flanges.

- We specialize in creating trays with tight-tolerance cavities that provide the precise product fit required in many automated pick-and-place processes.

- We offer both silicone-coated and internal denest material options to ensure consistent performance in automated dispensing processes.

Virtually Unlimited Material Experience

From food-grade materials to conductive and ant-static materials for electronics applications, the Indepak custom thermoforming team has the experience to design, specify and monitor the quality of all types of “thermoformable” plastics. We have systems in place for testing materials from the receiving process all the way through shipment.

We can also work with your team to utilize sustainable and recycled materials or design more environmentally friendly trays that use less material without sacrificing functionality.

Resources

Learn More About Thermoforming Trays

Ready to Get Started?

Request Quote

and/or Samples

Contact sales for volume pricing and

access to free samples for testing and

prototyping.

Contact a

Packaging Specialist

For help finding the best package for

your application or creating one that

is customized to your specific needs.

Shop Our

Online Store

For immediate access to our stock

packaging tubes, clamshells,

containers, caps and more.