Back in the 1960s when we first opened our doors, plastics were a fairly new player in the packaging industry, but plastics have transformed our healthcare system offering an affordable, secure way to protect medical devices, medicines, syringes and much more. Indepak has been at the forefront of plastic medical packaging since 1967 and we still deliver the highest-quality packaging for our medical and pharmaceutical clients, including medical trays, blister packs, clamshell packs and more.

Innovative Medical Packaging

If there’s one universal truth about packaging, it’s that the standards are constantly evolving and at Indepak, we not only provide customers with more than 50 years of experience, we also consistently provide our customers with the latest innovations in medical packaging and custom plastic packaging in general.

Quality & Consistency

At Indepak, we keep everything in-house and that includes design, prototyping and production. This not only drives down costs, but it also ensures quality. When it comes to medical trays and medical packaging, mistakes are simply not acceptable, and it’s crucial to find a packaging supplier that understands the intricacies of designing quality medical and pharma packaging.

Indepak Offers Customers the Following Benefits

- Low-particulate packaging

- Medical packaging for non-sterile or downstream sterilization applications

- Detailed record-keeping and traceability to the box level

- Custom designs & in-house prototyping

- A variety of sustainable materials

Types of Medical Packaging We Provide

Medical Trays

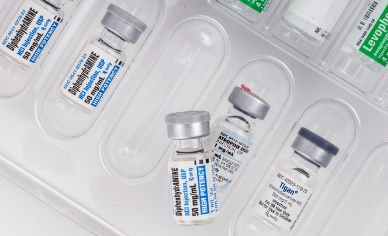

For surgical kits, medical devices, medical vials, medications, etc.

Blister Packaging

For medical devices, over-the-counter medications & more.

Clamshell Packaging

For medical devices, kits, medications, first aid items & more.

Innovative Designs

Our design team can create whatever plastic packaging you might need.

Rigid Plastic Packaging vs. Flexible Packaging

At Indepak, our focus is on designing and producing rigid plastic packaging, and we’ve stayed out of the flexible packaging sector. Rigid packaging materials are more protective than flex packs, and while the packages tend to be larger, they are easier to stack and store than flexible packaging. Keep in mind, that while we do not provide lidding films, we will work with your lidding supplier to ensure material compatibility.

Current Trends/Needs in Medical Packaging

Whether you need medical trays, blister packaging, clamshell packaging or something else, there are several aspects of medical packaging that we focus on when we begin any new custom packaging project, including the following:

User Experience

While security is crucial, accessibility is a huge factor. For instance, with kits used in an ambulance or emergency room, packaging designs should provide quick access for medical personnel without sacrificing sterilization. We also can design medical trays and other types of packaging that stack easily for optimum storage benefits.

Consumers also appreciate custom product packaging that can be opened easily, especially for those with mobility issues. However, in many cases, packaging also needs to be child-safe, and that can be addressed during the design phase. When we design your packaging, we will focus on your specific customer types to ensure that the packaging provides them with the best possible user experience.

Sustainability

When it comes to medical trays or any type of medical packaging, plastics have many advantages over other materials. Plastics are impact-resistant and moisture-resistant and can be sterilized easily. Their light weight and durability allow their use in many settings from field hospitals to ambulatory care to hospital settings. Still, the big trend these days is to increase packaging sustainability, and Indepak can help.

We offer a variety of recyclable plastics, as well as starch-based bioplastics, which might be a fit with some types of medical packaging. We also can provide you with plastics derived from recycled content, which reduces the need for virgin materials. Additionally, we are committed to minimizing our impact on the environment and strive to be a low-waste operation in every part of our company.

Security

For many of our healthcare-related clients, security is a top concern, which is why we provide detailed record keeping as this ensures traceability down to the box level. We have processes from material ordering and receiving through to production and packaging to ensure that your medical trays and medical packaging meets agreed-upon specifications. Whether you need packaging for non-sterile applications or you need packaging suitable for downstream sterilization, we can provide you with quality packaging that meets your criteria.

Fast Production Times

These days, especially after the pandemic, speed is the name of the game. Our facility includes multiple lines of high-speed thermoforming equipment allowing us to meet the needs of a diverse clientele. While we never want to sacrifice quality for speed, we can provide you with the highest quality medical packaging within a reasonable time frame. We also offer additional services such as inventory management and package fulfillment.

Our thermoforming equipment can process a variety of plastic materials, including ABS, HDPE, HIPS, OPS, PET, PETG, PP, PVC and starch-based bioplastics. Not all of these materials are suitable for all medical packaging, such as those intended for downstream sterilization applications. Our design team will study your product carefully to determine which material or materials could be the best fit for your packaging project.

Standards for Medical Packaging

At Indepak, we are ISO 9001:2015 certified. ISO is an international organization that sets exacting standards for many types of businesses, including packaging companies. The ISO 9001 standards refer to quality management systems and, at Indepak, quality assurance is a way of life from design to final delivery.